MMC

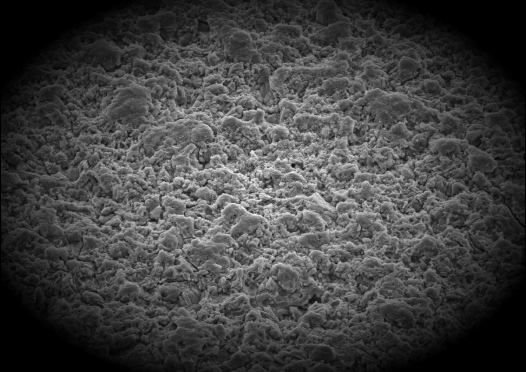

A metal matrix composite (MMC) is a composite material consisting of a metal matrix constituent into which the reinforcement material is embedded.

MMCs we mainly use are highly rigid Al-Sic composites consisting of aluminum matrix with silicon carbide particles. which achieve drastic weight saving and higher rigidity , combining the advantage of the two materials — lightweight and corrosion resistance of aluminum matrix and the hardness/stiffness of the silicon carbide.

Use of MMC composites

The MMC composites handled in our company are mainly used to make components of semiconductor and LCD manufacturing equipments, machine tools, inspection equipments.

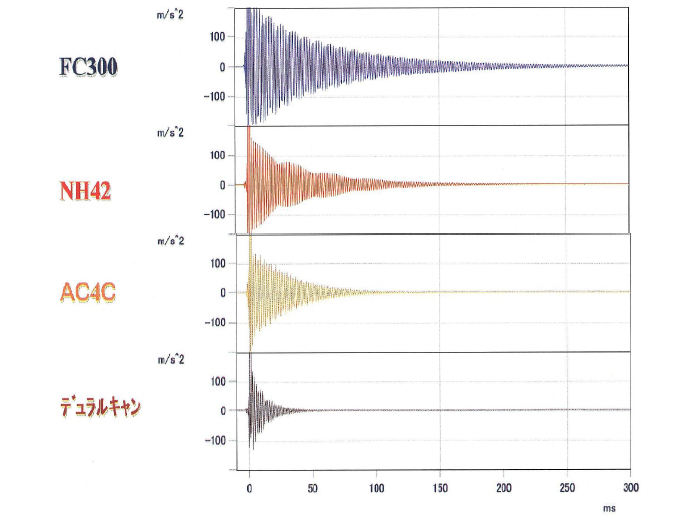

We make the best out of their characteristics such as weight savings, high stiffness and high damping. Our products, used in high-speed driving parts in machines and devices, contribute to speed-up, accelerate and assure higher functions, especially in large-dimension machine tools to cut and mill aircraft parts.

MMC composites also have worldwide attention of automotive industries. They are studied to achieve further weight-saving and to be introduced to undercarriage parts.

Our MMCs

Duralcan® composites

Duralcan® is a series of MMC commercialized by a Canadian alminum company Rio Tinto Alcan Inc.

Their range of MMC include alminum composites with 20% or 30%(in volume) silicon carbide which attires automotive industries. We handle both the Al-20vol%SiC and the Al-30vol%SiC , in casting and forging., to make Formed and Fabricated Materials

AKS-50・AKS-60

Our company’s original composites

containing 50% or 60% (volume ratio) of SiC.

Higher ratio of Sic affecting formability, we use a special casting technique to fabricate shaped raw materials from AKS composites, which might allow less liberty for modeling and forming compared to Duralcan® but have superior mechanical characteristics.

Mechanical characteristics of MMC

material characteristic

| Duralcan® 20vol% |

Duralcan® 30vol% |

AKS-50 50vol% |

AKS-60 60vol% |

FC300 | AC4C | |

|---|---|---|---|---|---|---|

| coefficient of thermal expansion(ppm/℃) 50~100℃ |

17.5 | 14.4 | 10.4 | 9.4 | 9.8 | 22.5 |

| density (g / cm³) |

2.77 | 2.78 | 2.93 | 2.97 | 7.25 | 7.71 |

| tensile strength (MPa) |

230 | 371 | – | – | 300 | 196 |

| Young’s modulus (GPa) |

97 | 125 | 167 | 201 | 133 | 71 |

| Poisson’s ratio | 0.3 | 0.29 | 0.27 | 0.25 | 0.26 | 0.33 |

| specific heat [J/(g・K)] |

0.84 | 0.82 | 0.85 | 0.81 | 0.52 | 0.88 |

| thermal conductivity [W/(m・K)] |

184 | 150 | 170 | 203 | 53 | 159 |

| Rockwell hardness (HRB) |

80 | 90 | 100 | – | 103 | 61 |

*Values for Duralcan®20%, Duralcan®30%, AC4C are those after the T6 treatment.

*Contact us for aptness of materials to the method you wish(sand mold casting・special casting・hot forging..).

材料特性

※ Duralcan® in the figure is MMC20%.

We will accompany your project from its budding, with our experienced knowledge and skills of molding and processing MMC materials that we have been developing since years. Do not hesitate to contact us.